Last updated on November 5th, 2021 at 06:00 pm

There are literally millions of promotional products, understanding how they are printed will help you ensure your artwork is presented in the best way possible. As print technologies advances, artwork that used to be impossible to print is now possible. As tech advances we’re going to see even more printed promotional products with unique artwork. Here are a few of the most popular promotional products print methods:

Pad printing is a process in which a plastic, glass, ceramic, metal, silicone, or wooden item can be decorated. The image is transferred from ink filled etched images in a printing plate to the part by way of a silicone pad. While transferring the image to the part, the silicone pad wraps around or takes the shape of the part without distorting the image. Pad printing normally take up to 4 spot colors (pre-mixed ink colors). It is one of the most common and cost effective promotional products print methods.

Common uses of pad printing: promotional pens, mugs, water bottles, stress balls.

Silkscreen printing, also known as screen printing is a printing technique that uses a porous mesh screen that has an ink blocking stencil transferred onto it. The stencil creates blocked and open areas in the screen that allow inks to flow through them and onto a substrate. Nearly any single ink image, logo or design can be transferred onto a screen. Additional colors require new screens. Silkscreening is printed with Pantone spot colors (pre-mixed ink colors).

Common uses of silkscreen printing: apparel, tote bags, water bottles

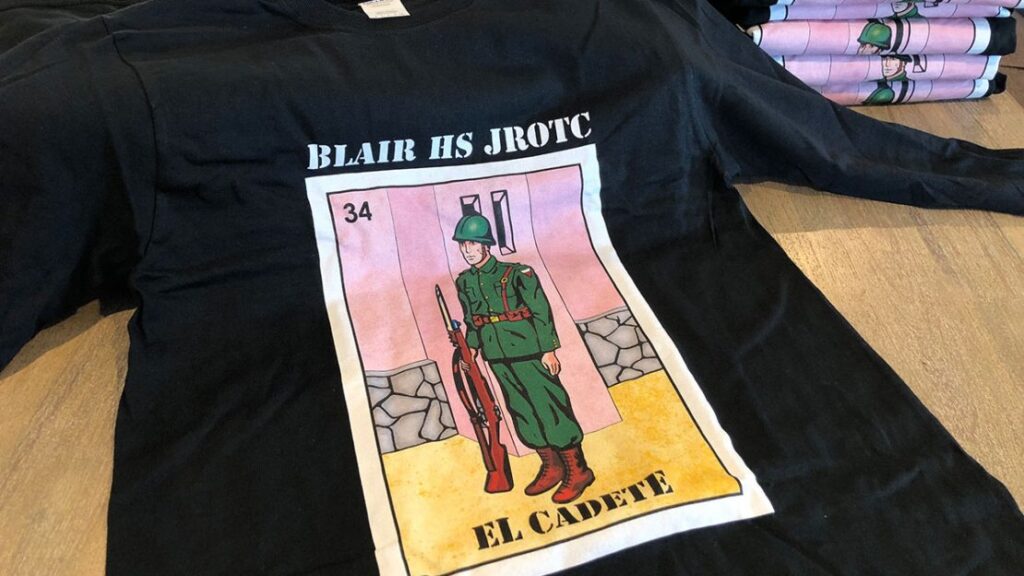

Full color digital printing is used when a logo contains many colors and gradients. This process does not use screens and generally allows you to print over the entire surface. Digital printing is also referred to as CMYK printing, full-color printing, color burst, and 4-color process printing. Since there is no screens involved, there is less setup and therefore works well for small quantity orders. This type of print promotional product is perfect if you’re ordering only a small batch.

Common uses of full color digital printing: buttons, posters, banners, water bottles, pens, cotton t-shirts

Full color dye-sublimation may seems a complicated process, but it is not. A full color image is printed onto a “transfer” paper, and then it is placed onto white fabric and ran through a series of pressure rollers and high heat. This permanently bonds the image directly onto the fibers of the fabric. Anything polyester or with polyester resin coating can be printed on with the dye sublimation process. Full color dye sublimation can open up more opportunities, allowing fully custom cut and sew apparel, bags, display.

Common uses of full color dye sublimation: apparel, display, tent, mug, mousepad

Laser engrave on promotional products are often found on wood, acrylic, textiles, stainless steel or glass products. The engraving method requires no consumerables such as inks, and is fast with very little setup time. Therefore a lot of products with personalization is laser engraved. Since the logo impression is physically on the item, the “imprint” will not scratch off and is long lasting.

Common uses of laser engrave: metal pens, stainless steel water bottles, crystal / glass / wood awards, leather goods

Heat transfer is a process similar to using an iron to press a decal onto a shirt. Printers use intense heat to press the ink into the material, making sure that your logo isn’t going anywhere. One color or full color designs are all possible on heat transfer. The same batch of transfers can be used on different apparel items, therefore it is a great way to decorate a small number of garments.

Common uses of pad printing: Hats, apparel, sports jerseys, tote bags

Deboss has been around for a long long time. Dies are constructed from metal in the shape of your logo. The product is then placed between them and heat and pressure push and form the material into the impression you want. For an additional cost, you can also fill color to the logo. The result is an elegant logo imprint where you can feel the indentation.

Common uses of deboss: leather notebook, leather padfolio, silicone bracelet

Embroidery is stitching the logo onto a piece of garment. In the embroidery process, your logo is changed to a digital image comprised of stitches and then assigned color threads. Then the garment is placed onto the embroidery machine which will execute the digitalized logo into threads. The result is a sophisticated and elegant representation of the logo that is long lasting. Read about our embroidery process here.

Patches are created by using a fabric backing and thread. The art of making patches is an old tradition and was originally done by hand. There are many different varieties of patches: embroidered patches, woven patches, leather patches etc.

Various methods are available for affixing them to the fabric surface – sewn on, or affixed with more modern methods such as iron-on, dryer heat-activated adhesive, and Velcro backing.

More questions about print promotional products?

Do you have specific questions about printing on promotional products or interested in ordering printed promotional products? Contact our team today! We would love to help.

About Garuda Promo & Branding Solutions

Led by a team of skilled professionals with years of experience in promotional items and advertising specialties, Garuda features a sourcing platform which includes more than 3,500 vendor partners. We offer manufacturing capabilities that cover any custom products imaginable. We serve companies large and small, with a mission to market our clients’ businesses with fun, out-of-the-box promotional products. Our experience enables us to imprint many promotional products right here in Los Angeles! Our policy of being on time, reliable and solving crises will help take your company to the next level. For Los Angeles area, call today (323) 379-4887. Our Claremont office number is (909) 547-4282. or contact us online.

Shirley is the co-founder of Garuda Promo and Branding Solutions. With a background in print production and graphic design, she specializes in promotional products marketing, creating end-products that aligns with her client's marketing goals and brand strategy.